Service quality and human contact are essential when purchasing an industrial machine. Given the investment made and the expectations in terms of performance, it is important to rely on quality contacts at every stage of the realization and evolution of your medical waste treatment project. It’s fundamental to be reassured, advised, helped and accompanied in such an endeavor. This is clearly the approach adopted by Ecosteryl, through the commitment of its different teams (sales, administrative or technical). Whether it involves accurately assessing needs, proposing the best technological solution, training the operators or optimizing the production of the machine, Ecosteryl has all the qualified and accessible human resources available internally. Objective: to build and maintain a long-lasting relationship with the client, considered as a real partner.

(Re)known for their robustness and long lifespan, Ecosteryl machines are designed and manufactured to disinfect medical waste over (very) many years. Equipping oneself with such technology also means committing to a long-term relationship with the manufacturer. That is why Ecosteryl takes special care in the quality of the services surrounding the purchase of a machine. Thanks in particular to the quality of its internal teams, composed of women and men, all dedicated to serving the end customer.

Far more than just a ‘commercial’ connection

Ecosteryl’s first strength lies in a team of about ten collaborators specialized in medical waste treatment across the globe. Any potential customer interested in the technology proposed by Ecosteryl will be put in contact with a collaborator who knows the market or the geographic area in which the prospect operates medical waste. He or she will first, of course, start by listening to the potential customer: What is his context? What is his market? What are his/her needs? What quantities of medical waste do they plan to treat? What are the specificities of the waste in this area? What are the regulations in force? Etc.

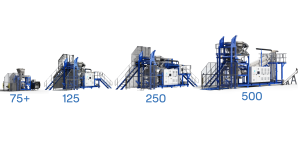

The objective being to propose the technological solution (Ecosteryl 75+, Ecosteryl 125, Ecosteryl 250, Ecosteryl 500, R-Steryl) best suited to the needs.

Ecosteryl’s project manager helps the prospect carry out a cost analysis. They study together the possible technical configurations to host the future machine. Ecosteryl’s project manager can also gather information to study the possible financial aids or other subsidies that could be available for the purchase of an ecological medical waste treatment machine.If needed, Ecosteryl’s project manager will refer to the Research & Development department or even to Ecosteryl’s technical service to provide additional information or details according to the situations presented.

The final goal being to give the prospect as many elements and answers as possible to help him make a just and thoughtful decision when investing.

“Putting yourself in the prospect’s shoes is the only way to answer them appropriately; that’s why we prefer to meet them on their own site, if possible,” explains Patrick Meurice, sales manager.

Once the machine is sold and operational, Ecosteryl’s project manager will of course stay in contact with the client to follow the progress and respond, if needed, to the questions or specific requests.Clients typically begin with the purchase of a first machine, but if they are delighted and their business is thriving, they may call on Ecosteryl again.The situation may, for example, be reassessed in case of new needs or major changes in his medical waste treatment activity (relocation, expansion, new markets, etc.). The salespeople all maintain very close ties with their respective clients.

We don’t always appreciate the value of human contact, yet “the relationship will last over 10 years — so it’s important to choose with whom you want to collaborate.” Ecosteryl always offers a visit to its plant (manufacturing and assembling of the machines) so that potential clients can immerse themselves in the seriousness and service of the teams, and the atmosphere.

An efficient administrative service

Buying an industrial machine usually comes with a whole series of important administrative procedures: contract management, invoicing, legal and regulatory compliance, certifications, budget, financing, logistics, insurance, etc. At this crucial stage of the process, Ecosteryl’s administrative service is also present to ensure together the administrative follow-up and guarantee the success of the transaction.

A highly responsive after-sales and technical service composed of highly qualified experts

Once the purchase of the machine is finalized, Ecosteryl’s after-sales service takes over to handle the installation, the technical support training, either remotely or on-site. Here too, Ecosteryl has a team of qualified and experienced experts and technicians, ready to travel to all corners of the world to guarantee the perfect installation of the machine and its optimal performance.

Once the purchase of the machine is finalized, Ecosteryl’s after-sales service takes over to handle the installation, the technical support training, either remotely or on-site. Here too, Ecosteryl has a team of qualified and experienced experts and technicians, ready to travel to all corners of the world to guarantee the perfect installation of the machine and its optimal performance.

The machine ordered, ready and tested in our assembly hall in Mons, will first be disassembled and carefully prepared for transport (by truck or ship).

The machine ordered, ready and tested in our assembly hall in Mons, will first be disassembled and carefully prepared for transport (by truck or ship). Once delivered to the proper destination, the machine will be installed, tested, and commissioned by our technicians. They will then train the operators in its use and maintenance. They will carefully check the first disinfection productions of medical waste and make the necessary adjustments to optimize the machine’s output. Thanks to their expertise, Ecosteryl’s technical experts will be able to best configure the machine, according to general production conditions and local specificities of the medical waste to be processed.

Once the machine is operational and in production, Ecosteryl’s after-sales experts remain accessible and available (email, WhatsApp…). Responsive, they can quickly answer the client’s questions or help remotely to resolve situations related to machine production.Note that in cases of force majeure or if the issue cannot be resolved remotely, Ecosteryl’s technicians will travel on-site to intervene within reasonable timeframes and ensure the proper functioning of the machine(s).

Once the machine is operational and in production, Ecosteryl’s after-sales experts remain accessible and available (email, WhatsApp…). Responsive, they can quickly answer the client’s questions or help remotely to resolve situations related to machine production.Note that in cases of force majeure or if the issue cannot be resolved remotely, Ecosteryl’s technicians will travel on-site to intervene within reasonable timeframes and ensure the proper functioning of the machine(s).

The after-sales service of Ecosteryl also has a stock of spare parts, which can be sent to the client as quickly as possible.

Long-lasting relationships

In conclusion, service quality and human contact play an essential role in the success of acquiring an industrial machine. Beyond the technical specifications and equipment performance, it is the relationship of trust and personalized support that truly makes the difference.

In conclusion, service quality and human contact play an essential role in the success of acquiring an industrial machine. Beyond the technical specifications and equipment performance, it is the relationship of trust and personalized support that truly makes the difference.

Ecosteryl understands this well, and presents itself as a listening partner, capable of understanding the specific needs of its clients, advising them effectively, and supporting them throughout the use of the machine.

Sustainability is not only about machines — it’s also about the client relationship. This is the very goal of the privileged customer relationships Ecosteryl promotes.

Would you like to start a relationship with Ecosteryl? Send us an email at sales@ecosteryl.com

For 20 years, Ecosteryl has been providing medical waste disinfection and sorting machines. The company is a market leader. Properly disinfecting medical waste is a critical concern, becoming even more crucial during health crises. History has proven this to be true. Inadequate treatment can have severe consequences.

Traditional methods such as direct incineration or autoclaving are now being questioned due to their environmental impact and the impossibility of recycling plastic.

Ecosteryl offers an innovative and cost-effective alternative with its 100% electric disinfection machines. Here, we highlight the key factors that make Ecosteryl the best choice for medical waste management.

An Eco-Friendly machine: 100% electric medical waste disinfection

Ecosteryl machines run exclusively on electricity, consuming between 20 and 80 kWh. Being fully electric, they emit no air pollutants, providing an environmentally friendly solution for medical waste treatment. That is why various international organizations, including the World Health Organization (WHO), the United Nations, the World Bank, and Ministries of Health and Environment, strongly recommend these technologies.

A high level of disinfection

Ecosteryl’s primary mission is to ensure the highest level of medical waste disinfection. With over 20 years of experience, Ecosteryl provides proven and internationally recognized technology.

Ecosteryl’s primary mission is to ensure the highest level of medical waste disinfection. With over 20 years of experience, Ecosteryl provides proven and internationally recognized technology.

The disinfection level reaches at least 6 log10 (99.9999%). Moreover, Ecosteryl complies with the French standard NF X30-503, one of the strictest in the world. Therefore, Ecosteryl machines guarantee optimal disinfection.

Continuous processing

A key advantage of Ecosteryl is its continuous treatment process. Waste is continuously fed into the machine (a container of approximately 50 kg is pushed every 10 minutes on average for the Ecosteryl 250), and disinfected waste is discharged simultaneously.

A key advantage of Ecosteryl is its continuous treatment process. Waste is continuously fed into the machine (a container of approximately 50 kg is pushed every 10 minutes on average for the Ecosteryl 250), and disinfected waste is discharged simultaneously.Unlike batch processes, this eliminates waiting time for operators and improves efficiency.

The Ecosteryl 250 can process a minimum of 250 kg per hour, making it a unique solution in the medical waste industry outside of incineration.

Other technologies require an operator to wait for the cycle to complete before emptying and refilling the machine. Ecosteryl is valued for its ease of use and efficiency.

A powerful shredder

Pre-shredding waste is essential for effective disinfection. Ecosteryl machines are equipped with a robust four-axis shredder, reducing waste to a maximum size of 35 mm.

The shredder features an anti-jamming system to prevent blade damage.

A well-shredded final output ensures better sorting efficiency for recycling centers.

Durability and reliability

Ecosteryl machines are designed and manufactured to last. Their weight and construction reflect their robustness.

Ecosteryl machines are designed and manufactured to last. Their weight and construction reflect their robustness.

Key components, including shredders, electrical cabinets, microwaves, and sensors, are sourced from the best technical suppliers on the market.

Since Ecosteryl machines primarily consist of electronic and mechanical parts, each component can be replaced over time, extending the machine’s lifespan beyond 20 years.

This factor is crucial for cost analysis and ROI calculations.

A range of machines to suit different needs

To cater to various market demands, Ecosteryl offers four machine models, capable of treating 75 to 500 kg per hour: Ecosteryl 75+, Ecosteryl 75+, Ecosteryl 125, Ecosteryl 250, Ecosteryl 500. Choose the right machine based on your operational hours and expected growth.

Easy installation and relocation

Ecosteryl machines are easy to install and operate. Installation takes one week, followed by on-site training provided by Ecosteryl experts.

Ecosteryl machines are easy to install and operate. Installation takes one week, followed by on-site training provided by Ecosteryl experts.

Need to relocate the machine after a few years? No problem! Since no gas or water connections are required, Ecosteryl machines can be easily moved.

Many clients have already done this successfully.

Easy maintenance

When purchasing, you can additionally obtain a spare parts kit (consumables) valid for 2 years.

When purchasing, you can additionally obtain a spare parts kit (consumables) valid for 2 years.

Your team is trained to perform routine maintenance. If issues arise, our 24/7 technical support is available via phone, WhatsApp, or email.

Our experts can even remotely connect to your machine (if you allow it) for assistance. In almost 100% of cases, this is sufficient.

We also provide detailed weekly, monthly, and annual maintenance guidelines, which focus mainly on preventive measures.

The only complex maintenance required is replacing the shredder blades, typically after 1,200 tons of processed waste (for the Ecosteryl 250).

Additionally, Ecosteryl maintains a permanent stock of spare parts, ensuring fast delivery to minimize downtime.

Reduced operating costs

Since Ecosteryl machines run solely on electricity, they do not require water, gas, or other expensive resources.

This keeps operating costs low. Furthermore, one operator can manage two machines at once, further reducing labor expenses.

A dry, recyclable final waste output

Thanks to dry heat disinfection, treated waste comes out dry and unrecognizable.

Thanks to dry heat disinfection, treated waste comes out dry and unrecognizable.With the R-Steryl sorting technology, this waste can be recycled, contributing to a circular economy in medical waste management.

This is a unique advantage in the industry, as Ecosteryl’s process ensures waste is both dry and optimally shredded for recycling.

Machine data analysis to optimize productivity

Our expert team can assist in data analysis to help improve your operations.

Traveling? Want to check if your team processed enough waste yesterday? Simply log in from your computer or smartphone.

A safe and secure work environment

Safety is a top priority for Ecosteryl.

Safety is a top priority for Ecosteryl.

From design to operation and maintenance, every aspect of the machine is built with operator and workplace safety in mind.

Ecosteryl machines comply with strict international safety standards (CE, etc.) and integrate multiple preventive safety features such as alarms, alerts, and sensors.

Recognized commitment to sustainability

The company is also endorsed by the Solar Impulse Foundation.

Several major organizations, including the WHO, World Bank, and United Nations, have chosen Ecosteryl machines for large-scale projects.

These advantages are widely appreciated by our satisfied clients.

Our top priority is customer satisfaction. Feel free to contact or visit our clients to hear their feedback.

After several years of research and testing, Ecosteryl is launching a new machine: the Ecosteryl 500. This is the largest machine in the range, capable of processing double the current capacity, up to 500 kg per hour.

Until now, Ecosteryl’s best-selling machine was the Ecosteryl 250, which can disinfect 250 kg per hour and is widely used around the world. This new machine provides large companies and service providers with an easier solution to equip themselves. (more…)

Since July 2024, we have joined the beautiful and prestigious community of companies labeled as ‘B Corp’ worldwide. It is indeed a source of pride, but also recognition for Ecosteryl, which has consistently made efforts, taken initiatives, and committed to embedding social and environmental responsibility at the core of its economic activities