01. Weighing

A waste container (wheelie bin) is placed on the automated loading system of the machine. An industrial scale records the loaded waste weight. (applies to models 125 and 250).

Contact us

Contact us

a world without infectious waste. We could help you to achieve that.

Sorting and circular economy thanks to R-steryl

A waste container (wheelie bin) is placed on the automated loading system of the machine. An industrial scale records the loaded waste weight. (applies to models 125 and 250).

Loading is automated: as soon as the loading hopper is empty, a new container is loaded. (applies to models 125 and 250).

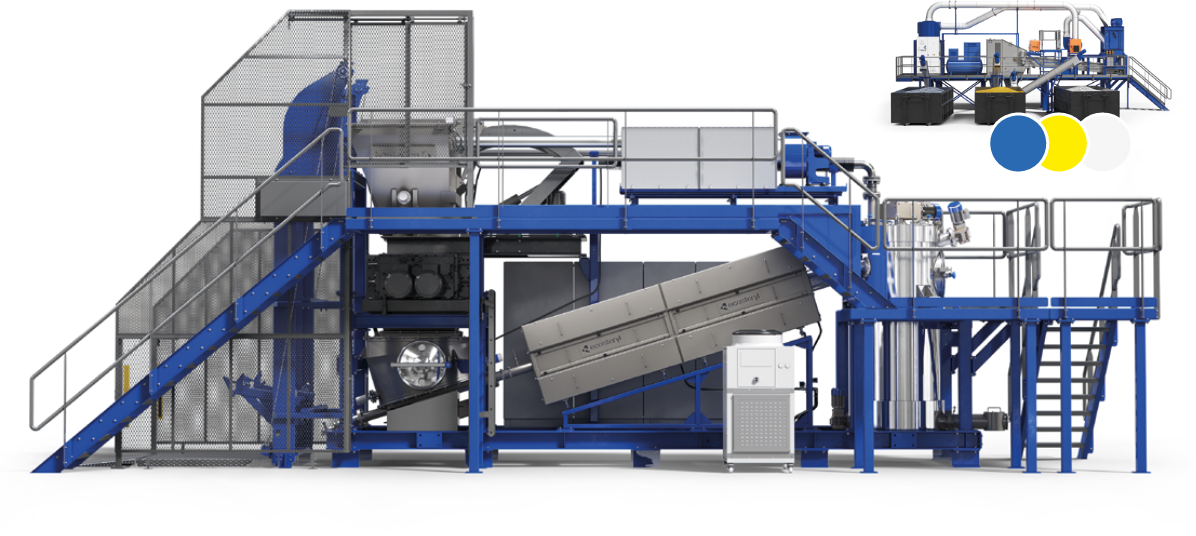

A powerful, reliable and slow industrial shredder reduces the medical waste volume up to 80%. The 4 axes and a screen that was specially developed by Ecosteryl ensure a calibrated shredding. Several systems ensure the optimal operation of the shredder, preventing any damage to its cutting mechanism (via an anti-blocking system).

In less than three minutes, the waste reaches a temperature of around 100°C at the microwave tunnel end. An automated control system guarantees the quality of the preheating.

The heated waste is kept for one hour in the tank at a temperature of around 100°C. The combination of these two parameters (time and temperature) ensures full disinfection. The waste which exits the machine is disinfected, dry and unrecognizable. It can directly join the traditional household waste collection route or be sent to the R-Steryl sorting center.

The disinfected waste is supplied to the R-steryl sorting center. It is sorted by size and color, according to the customer’s defined parameters.