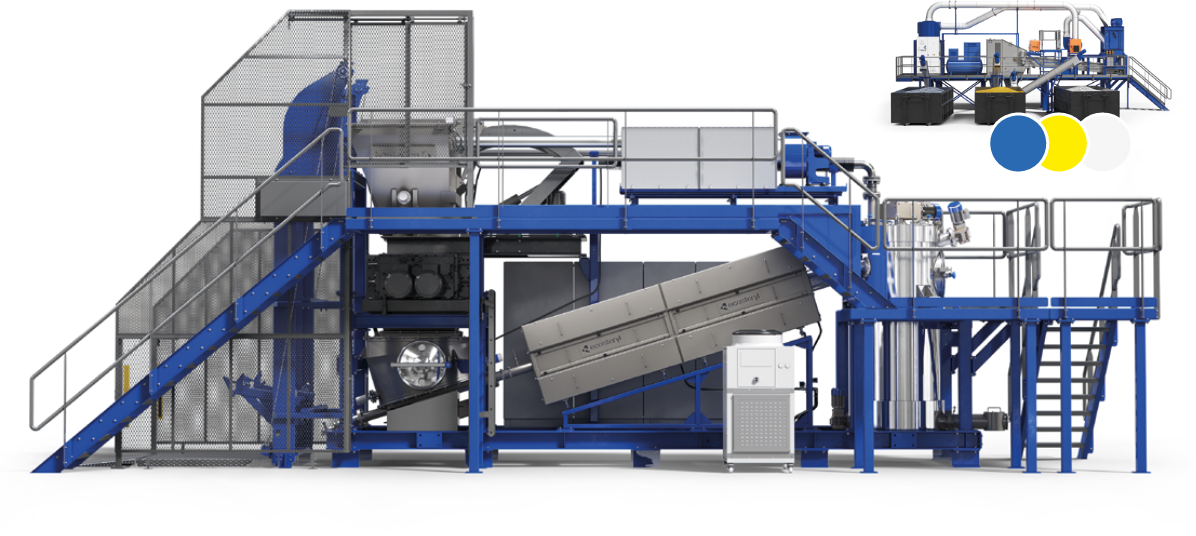

01. Weighing

A waste container (wheelie bin) is placed on the automated loading system of the machine. An industrial scale records the loaded waste weight. (applies to models 125 and 250).

Contact us

Contact us

A fully electric dry heat process

Sorting and circular economy thanks to R-steryl

A waste container (wheelie bin) is placed on the automated loading system of the machine. An industrial scale records the loaded waste weight. (applies to models 125 and 250).

Loading is automated: as soon as the loading hopper is empty, a new container is loaded. (applies to models 125 and 250).

A powerful, reliable and slow industrial shredder reduces the medical waste volume up to 80%. The 4 axes and a screen that was specially developed by Ecosteryl ensure a calibrated shredding. Several systems ensure the optimal operation of the shredder, preventing any damage to its cutting mechanism (via an anti-blocking system).

In less than three minutes, the waste reaches a temperature of around 100°C at the microwave tunnel end. An automated control system guarantees the quality of the preheating.

The heated waste is kept for one hour in the tank at a temperature of around 100°C. The combination of these two parameters (time and temperature) ensures full disinfection. The waste which exits the machine is disinfected, dry and unrecognizable. It can directly join the traditional household waste collection route or be sent to the R-Steryl sorting center.

The disinfected waste is supplied to the R-steryl sorting center. It is sorted by size and color, according to the customer’s defined parameters.

Infectious medical waste is considered a risk and cannot follow the traditional household waste stream.

To avoid health risks, it is placed in specific containers and must be rapidly disinfected.

All types of medical waste (liquid and solid) considered infectious, including human or animal pathological waste.

Prickly, sharp and cutting waste.

Cytotoxic and radioactive waste, in accordance with international guidelines.

Comparing before choosing

| Ecosteryl (dry microwave process) | Autoclave (hot steam process) | Autoclave with a shedder | Incinerator (high-heat process) | |

|---|---|---|---|---|

| Characteristics | ||||

| Continuous process | ||||

| Integral shredding | ||||

| Unrecognizable waste | ||||

| Waste volume reduction | ||||

| Waste weight reduction | ||||

| Installation requirements | Low | High | High | High |

| Installation complexity | Low | Intermediate | Intermediate | High |

| Possibility on In-situ installation | ||||

| Approved and recognized technology by countries all over the world | High | Intermediate | High | Low |

| Decontamination level | High | Intermediate | High | High |

| Odours | Low | High | High | Intermediate |

| Noise | Low | Intermediate | Intermediate | High |

| Treatment of pathological and anatomical waste |

| Ecosteryl (dry microwave process) | Autoclave (hot steam process) | Autoclave with a shedder | Incinerator (high-heat process) | |

|---|---|---|---|---|

| Costs | ||||

| ROI | High | Low | Low | Low |

| Investment costs | Intermediate | Low | Intermediate | High |

| Operating costs | Low | High | High | High |

| Maintenance costs | Low | High | High | High |

| Labour costs | Low | High | High | High |

| Ecosteryl (dry microwave process) | Autoclave (hot steam process) | Autoclave with a shedder | Incinerator (high-heat process) | |

|---|---|---|---|---|

| Environment | ||||

| Impact on the environment | No | Intermediate | Intermediate | High |

| Treated waste recyclable | ||||

| No contaminated rejection (such as water, steam) |

| Ecosteryl (dry microwave process) | Autoclave (hot steam process) | Autoclave with a shedder | Incinerator (high-heat process) | |

|---|---|---|---|---|

| Safety | ||||

| No risk related to pressurized vessel | ||||

| Risk for workforce/personnel health (no risk of toxic contaminants released into the air or the treated waste) | No | Intermediate | Intermediate | High |